Stm32F103C8T6 bluepill controls RGB LED WS2811 IC non-DMA method

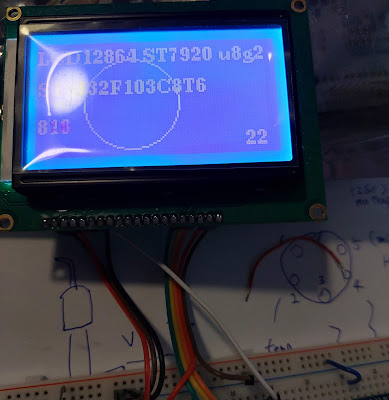

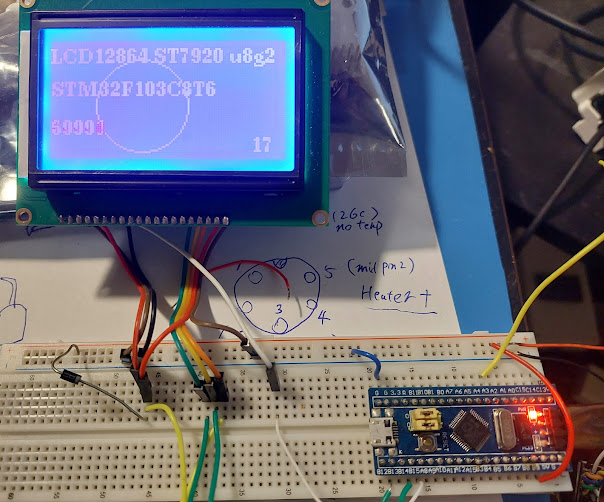

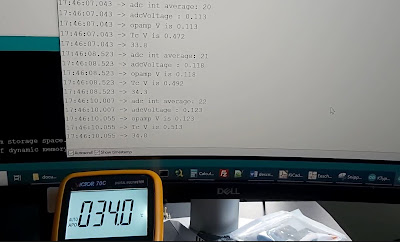

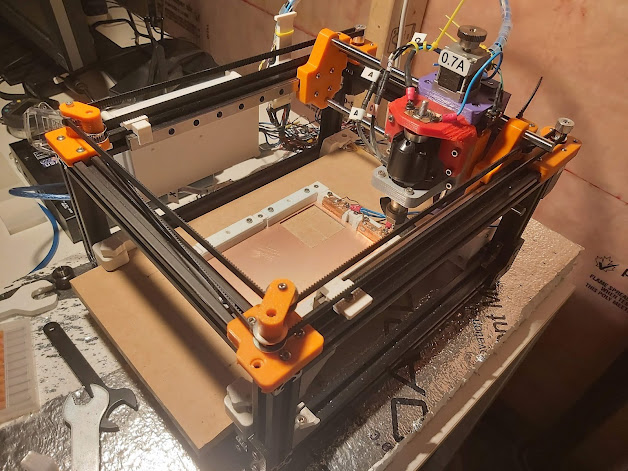

STM32F103C8T6 bluepill controls RGB LED WS2811 IC using non-DMA method IDE: STM32CubeIDE MCU: stm32F103C8T6 bluepill or black pill (STM32F401CCU6) Category: RGB LED IC: WS2811 ( Using a RGB LCD Screen, it has 3 RGB Leds, 3 WS2811 ICs) Oscolliscope: useful and helpful Intro There are quite some tutorials in Internet about the topic, however many of those are using DMA method. DMA is very useful in many use cases however not in mine, so I decided to investigate the non DMA method. I want to simply toggle GPIO to send the correct signal to the IC to make it work. WS2811 is a RGB IC, each IC controls one RGB LED (Neopixel ?), for example if we have 3 RGB LEDs, we need 3 WS2811. Any WS2811 RGB product should work with this source code / method, I am using a RGB LCD screen, It's made by Makerbase and made for 3D printer / Marlin firmware to use, originally. Since I don't have any RGB LED strip, this RGB LED is a very good test candidate. In case you have the sa...